Building the perfect boat is like creating a work of art. It needs careful attention to every detail. Even skilled designers can make mistakes that affect a boat’s performance, safety, and comfort. So, what are these common errors, and how can you avoid them? Let’s find out.

In this detailed guide, we’ll look at 10 common boat design mistakes. We’ll teach you how to steer clear of them. We’ll cover everything from bad framing to problems with the engine and exhaust systems. It’s important for every boat owner and buyer to know these key design points.

Are you making any of these common boat design mistakes without knowing it? Learn how to build a boat that is safe, efficient, and comfortable. It will be your trusted companion for many years.

Key Takeaways

- Understand the importance of proper framing, bulkheading, and hull side support for a boat’s structural integrity.

- Learn how to design a robust propulsion system that optimizes weight distribution and hydrodynamics.

- Explore best practices for designing efficient bilge systems and preventing exterior upholstery and decorative flaws.

- Discover the common pitfalls in engine exhaust and fuel system design, and how to avoid them.

- Gain insights into marine engineering considerations, such as engine mounts and plumbing systems, for a seaworthy boat.

Inadequate Framing and Support

Building a strong boat starts with good design. Sadly, many boats have boat hull design flaws and structural boat design problems. These issues can harm the boat’s strength and how well it works.

Insufficient Bulkheading

Boats usually have only one or two bulkheads, not the 12 or more needed. This boat bulkhead issue can cause big problems. Problems like hull twisting, loose parts, and leaks can happen. Having enough bulkheads is key to keeping the boat strong and preventing these issues.

Flexing Decks

Another common problem is flexible boat decks. This often comes from not enough bulkheads. Deck flexing can lead to leaks around hatches, windows, and other parts. This makes the boat less weather-tight and causes maintenance troubles for owners.

Lack of Hull Side Framing

Not enough boat side framing is another mistake. Without it, the boat’s sides can bend or flex. This can cause problems with the deck-to-hull joint, loose rub rails, and more leaks. Ignoring this important part can weaken the boat’s strength and safety at sea.

Fixing these boat hull design flaws and making sure the design is strong can help. Boat builders and owners can make boats that last longer and perform better.

Improper Structural Support for Cabin and Bridges

One big problem with boat design is the lack of support for the cabin and bridges. Cabin tops and flying bridges often rely too much on window frames. This can lead to leaks and cracked windows.

These issues usually come from bad planning and engineering. Builders might forget to include strong support for the cabin and bridges. This makes the boat weak and hard to fix.

Another issue is the poor framing of boat windows. Badly designed window frames can cause leaks and cracks. This weakens the cabin and bridges, especially when they’re exposed to the weather.

| Common Boat Cabin and Bridge Design Flaws | Potential Consequences |

|---|---|

| Lack of dedicated structural support for cabin and bridges | Chronic leaks, cracked windows, and costly repairs |

| Inadequate window framing | Compromised structural integrity, leaks, and deterioration |

| Overreliance on window frames for structural support | Fragile and vulnerable construction, susceptible to damage |

To fix these problems, we need to focus on good engineering and building. A well-made cabin and bridge improve the boat’s performance and safety. They also make the boat more enjoyable for everyone on board.

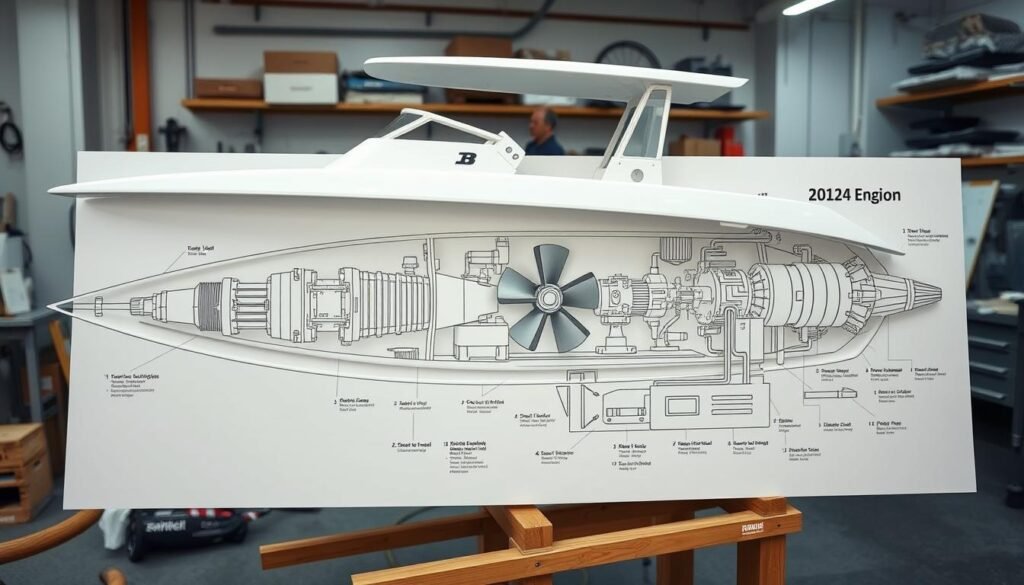

Flaws in Propulsion System Design

Designing a boat’s propulsion system is key to its smooth operation. Even experienced builders can miss important details. Two common mistakes are hull stringers that are too narrow and propeller shaft struts that are too small.

Insufficient Width-to-Height Ratio of Hull Stringers

When stringers are not wide enough, the hull can flex. This can harm the engine mounts and drivetrain. It leads to constant maintenance and serious structural issues. It’s vital to get the stringer dimensions right to keep the boat stable.

Inadequately Sized Propeller Shaft Struts

Small propeller shaft struts cause many problems. They can leak, vibrate, wear out bearings, and loosen bolts. Making sure the struts are the right size is crucial to avoid these issues.

Fixing these design flaws can make boating safer and more enjoyable. It ensures a smoother ride for everyone on board.

| Issue | Impact | Solution |

|---|---|---|

| Insufficient Width-to-Height Ratio of Hull Stringers | Hull bottom flexing, damage to engine mounts and drivetrain | Ensure proper stringer dimensions to maintain structural integrity |

| Inadequately Sized Propeller Shaft Struts | Leaking stuffing boxes, vibration, bearing wear, loose bolts | Properly dimension propeller shaft struts to prevent drive train issues |

Bilge System Deficiencies

Keeping your boat’s bilge system in good shape is key to avoiding floods and keeping everyone safe. But, many boat owners face common bilge system problems. These issues can cause big problems if not fixed.

Poorly Designed Bilge Spaces

One big issue is the design of bilge spaces. Often, the cabin sole is just inches from the hull bottom. This makes it hard to get to and fix the bilge pump. Such tight spaces can cause clogs or pump failures, raising the risk of water flooding your boat.

Insufficient Bilge Pumping Capacity

Another problem is when bilge pumps don’t have enough power. Many boats only have one pump, which can fail and leave the boat open to flooding. If water leaks in or pours in fast, one pump can’t handle it. This puts your boat and everyone on it at risk.

To avoid these boat bilge system design problems and reduce boat flooding risks, it’s vital to plan the bilge system well. Make sure it’s easy to maintain and has enough power for emergencies. Ignoring these important design points can lead to bilge pump and float switch problems. These can ruin your boating experience.

“Proper bilge system design is the unsung hero of boat safety. Don’t wait for a crisis to address these often-overlooked boat design issues.”

Exterior Upholstery and Decorative Flaws

Boat design faces big challenges with exterior upholstery and decor. Builders often use upholstered plywood and decor outside, not meant for the weather. This causes early wear and tear, harming the boat’s look and use.

Boat exterior upholstery problems include fast fading and cracking of materials. Sun, rain, and saltwater damage the fabric, making it brittle and ugly. Also, plywood can swell and fall apart, making things worse.

To fix these weatherproofing boat interiors issues, designers should pick durable, weather-resistant materials. Marine-grade vinyl, leather, or outdoor fabrics work well for seats. Also, using marine-grade plywood or composites helps prevent swelling and delamination.

- Avoid using standard upholstered plywood for exterior seating modules

- Choose marine-grade fabrics and materials that are designed to withstand outdoor exposure

- Ensure the underlying structure is made of weather-resistant materials like marine-grade plywood or composites

- Regular maintenance and cleaning can help extend the life of exterior upholstery and decorative elements

By choosing the right materials and methods for exterior upholstery, boats can stay beautiful and functional. This is key for a great boat design.

How to Avoid Common Boat Design Mistakes

Building a sturdy and well-designed boat needs careful attention and a good grasp of construction best practices. To avoid common mistakes, it’s key to team up with seasoned boat designers and builders. They focus on making boats strong, safe, and long-lasting.

Getting a detailed pre-purchase boat survey is a smart move. A professional surveyor will check the boat’s key parts, like the hull, frame, engine, and wiring. This ensures the boat is ready for the sea and meets your needs.

- Choose reputable boat designers and builders known for quality and safety.

- Make sure to get a thorough pre-purchase boat survey to spot any hidden issues.

- Keep up with the latest in boat building to make smart choices when buying or upgrading.

By being proactive, you can lower the chance of running into common boat design errors. This way, your boat will be safe, reliable, and fun to use for many years.

“The key to avoiding costly boat design flaws is to work with experienced professionals who prioritize quality and safety above all else.”

| Boat Design Element | Importance of Proper Design |

|---|---|

| Framing and Support | Ensures the structural integrity of the boat, preventing flexing and potential failures. |

| Propulsion System | Proper design and sizing of the propulsion components, such as the hull stringers and propeller shaft struts, is crucial for efficient power delivery and maneuverability. |

| Bilge System | An effective bilge system is essential for managing water intrusion and maintaining the boat’s stability and buoyancy. |

Exhaust and Fuel System Pitfalls

Boat design often faces challenges in the engine exhaust system and fuel tank installation. These issues can lead to water intrusion, fire hazards, and explosions. It’s crucial to avoid these problems for the safety and performance of the boat.

Improperly Designed Engine Exhaust Systems

One major issue is the placement of the transom outlet. If it’s too low, water can get pushed back into the engine. This can damage the engine and cause operational problems.

Another problem is exhaust tubing that’s too narrow or has sharp bends. This restricts airflow, causing backpressure and higher engine temperatures. It can lead to poor engine performance and damage.

Improperly Installed Fuel Tanks

Boat owners also face risks from fuel tanks not installed correctly. One issue is mounting aluminum tanks on plywood decks exposed to bilge water. This can cause corrosion, leading to fuel leaks and fire risks.

Also, fuel tanks placed too low or too far aft can affect the boat’s balance. This makes the boat more likely to tip or capsize in rough seas.

| Boat Exhaust System Design | Fuel Tank Installation Issues |

|---|---|

| Transom outlet placement too low Inadequately sized or improperly routed exhaust tubing Restricted airflow leading to backpressure and engine overheating | Mounting aluminum tanks on plywood decks exposed to bilge water Improper tank placement affecting boat balance and stability Increased risk of fuel leaks, fire, and explosion |

By fixing these common problems, boaters can greatly reduce risks. This includes water intrusion, fire, and explosion. It improves the safety and performance of their boats.

Marine Engineering Oversights

Even the most skilled marine engineers can miss important parts in boat design. This can cause big problems later. Weak or small engine mounts and bad plumbing systems are common mistakes.

Weak or Undersized Engine Mounts

The engine is key to a boat’s movement. Engine mounts keep it steady. If these mounts are weak or too small, the engine can move too much.

This can mess up the engine’s alignment and harm other parts. It might also cost a lot to fix and could be dangerous for those using the boat.

Poorly Designed Plumbing Systems

Boat plumbing is another area where mistakes often happen. If the materials or installation are not right, leaks and water damage can occur. These problems can be a hassle or even dangerous, depending on how bad they are.

To steer clear of these issues, boat makers need to focus on engine mounts and plumbing. They must use the right materials and install them correctly. This ensures the boat is safe and reliable for a long time.

“Attention to detail is paramount in marine engineering. A small oversight can have far-reaching consequences for the boat’s performance and safety.”

By fixing these common mistakes, boat designers can make boats that look good and work well. This gives customers a better boating experience.

Conclusion

Understanding common boat design mistakes is key. It helps buyers and owners ensure their boats are safe and fun to use. This article covered issues like bad framing and propulsion system problems.

Getting a pre-purchase boat survey is crucial. A marine surveyor can spot any design or construction issues. This way, buyers can make smart choices and avoid future problems.

By knowing these common mistakes, boat lovers can make better choices. They can enjoy the sea with confidence in their boat’s quality.

FAQ

What are some common boat design mistakes that can compromise performance, safety, and comfort?

Common mistakes include not enough bulkheading, decks that flex, and missing hull side framing. Also, cabin tops and flying bridges without proper support, bad propulsion system design, and bilge system flaws. Exterior upholstery and decorative elements can also be problematic.

How can inadequate bulkheading and hull framing lead to problems with a boat?

Not enough bulkheading can cause hull twisting and leaks. It also leads to loose fittings. Hull side framing issues can make the sides flex, causing deck-to-hull joint problems and leaks.

What problems can arise from poorly designed cabin tops and flying bridges?

Cabin tops and flying bridges supported mainly by window frames can leak and crack. This design flaw is hard and expensive to fix.

How can issues with the propulsion system design affect a boat’s performance and reliability?

Bad stringer design and small propeller shaft struts can cause hull flexing. It also damages engine mounts and drivetrain parts. This leads to leaks, vibration, and quick cutlass bearing wear.

What are some common problems with boat bilge systems?

Poor bilge design makes it hard to access and service the pump. Not enough bilge pumping capacity can cause water intake and sinking risks.

How can using improper materials and installation methods for exterior upholstery and decorative items affect a boat?

Exterior upholstered items not made for outdoor use can deteriorate quickly. This affects the boat’s look and function.

What are some common issues with boat exhaust and fuel systems?

Bad engine exhaust systems can push water back into the engine. Incorrect fuel tank installation, like aluminum tanks on plywood decks, poses fire and explosion risks.

How can weak or undersized engine mounts and poorly designed plumbing systems affect a boat?

Weak engine mounts can cause engine movement and damage. Bad plumbing can lead to leaks, water damage, and other issues.