Imagine gliding across a serene lake, the gentle rhythm of your paddle dipping into the water. You admire the stunning natural scenery around you. Building your own custom wooden canoe can make this a reality. But where do you start? The secret is finding the right DIY canoe plans and blueprints.

In this guide, you’ll learn the joy of building your own canoe. We’ll cover everything from choosing the right design to mastering cedar strip construction. Whether you’re experienced or a beginner, our plans and resources will help you create a unique vessel. It will be your trusted companion on the water.

But first, have you ever wondered about the secrets in a homemade canoe’s blueprint? Discover the magic of DIY boat building and unleash your creativity. Are you ready to start this amazing journey?

Key Takeaways – DIY Canoe Plans

- Discover the joy and satisfaction of building your own custom wooden canoe using DIY plans and blueprints.

- Explore a wide range of design options to find the perfect canoe that suits your needs and skill level.

- Master the intricate cedar strip construction process, from selecting the right materials to shaping the hull.

- Learn from expert guidance and resources to ensure a successful and rewarding DIY canoe building experience.

- Unlock the hidden potential of your creativity and craftsmanship by diving into the world of homemade boat building.

Introduction to DIY Canoe Building

Building your own canoe can be very rewarding. It’s great for those who love the outdoors or enjoy woodworking. Making a DIY wooden canoe is a fun and challenging project.

Benefits of Building Your Own Canoe

- Satisfaction of creating a unique, personalized watercraft

- Opportunity to develop valuable woodworking skills

- Potential cost savings compared to purchasing a pre-built canoe

Overview of the Cedar Strip Canoe Construction Process

The cedar strip canoe method is very popular. It involves several steps. First, you build a strongback. Then, you mill and prepare the cedar strips.

Next, you bend and attach the stems. Finally, you strip the hull. This makes a strong, custom canoe. It shows off your skills and creativity.

“The process of building a canoe from scratch is not only a rewarding challenge, but it also allows you to create a unique, personalized watercraft that truly reflects your style and vision.”

Preparing the Strongback and Molds

The first step in making a beautiful cedar strip canoe is building the strongback and molds. The strongback is a long, narrow table that supports the canoe. On top, the molds are placed to shape the canoe’s hull.

Starting the wooden canoe building process means careful planning and precise measurements. The strongback must be perfectly level and straight. This provides a stable base for the mold work. The molds are made from plywood, matching the canoe’s shape and size.

- Construct a sturdy, level strongback.

- Cut plywood molds to the appropriate shapes and sizes.

- Securely mount the molds at evenly spaced intervals along the strongback.

“The foundation of any successful canoe build is the strongback and mold system. Get this right, and the rest of the process will flow smoothly.”

With the strongback and molds ready, the next steps are milling the cedar strips and shaping the hull. This initial phase is crucial. It sets the stage for a remarkable, custom-crafted canoe.

Milling and Preparing the Cedar Strips

Building a cedar strip canoe starts with preparing the cedar strips. You can either order pre-milled strips or cut your own. It’s important to route the edges with a bead and cove joint. This makes the strips fit tightly around the molds.

Ordering Pre-Milled Strips vs. Cutting Your Own

Buying pre-milled strips saves time and effort. The supplier has already shaped the edges. This is great for beginners who don’t need special tools. But, cutting your own strips lets you customize and might save money if you have the right tools.

Routing the Bead and Cove Joints

Whether you buy pre-milled strips or cut them yourself, you need to route the edges. A bead and cove joint makes the strips fit together well. Use a router table or a handheld router with a jig to shape the edges.

“The key to a successful cedar strip canoe build is in the preparation of the cedar strips. Taking the time to ensure the edges are properly routed will pay dividends down the line.”

| Ordering Pre-Milled Strips | Cutting Your Own Strips |

|---|---|

| Time-saving, convenient for beginners | Allows for greater customization, potentially lower costs |

| Bead and cove joints already formed | Requires specialized equipment and skill to create bead and cove joints |

| Consistent quality and precision | Potential for variation in strip quality and joint precision |

Bending and Attaching the Stems

Making a canoe is a detailed task, and building the stems is key. The stems are the canoe’s ends and are very important. We’ll look at how to soak, bend, and glue ash strips for the stems.

Soaking and Bending Ash Stem Strips

To shape the stems, the ash strips need to be soaked in hot water. This makes them soft and easy to bend. After soaking, the strips are bent around molds to fit the canoe’s design.

Gluing the Inner and Outer Stems

After bending, the strips are glued together for the inner and outer stems. The inner stems go directly on the hull, giving the canoe strength. The outer stems finish the canoe’s ends, making it look good.

Building the canoe stems is a big part of making a canoe. By learning to soak, bend, and glue the stems, DIY builders can make canoes that are strong and look great.

“The stems are the heart of the canoe, shaping its character and defining its personality. Mastering their construction is a true testament to the skill and dedication of the DIY canoe builder.”

Stripping the Hull

With the stems in place, it’s time to start stripping the hull of your cedar strip canoe. This step involves stapling and gluing cedar strips onto molds. It’s important to follow the canoe’s shape carefully. This process is key to making a strong and smooth cedar strip canoe hull.

Stapling and Gluing Cedar Strips

Begin by placing the first cedar strip along the mold. Make sure it lines up with the stems’ bottom edge. Use a staple gun to hold the strip in place, making sure it fits the mold’s curves. Apply a lot of glue to the joint where the strip meets the mold, then press it firmly into place.

Keep adding strips, overlapping each one slightly. This will cover the mold completely.

Handling Challenging Curves and Shapes

Working with curved canoe shapes can be hard, but there are ways to make it easier. Instead of using one wide strip, try using several smaller ones. This helps with tight curves. You can also bend the strips before attaching them to the mold. This makes them more flexible and easier to shape.

| Technique | Benefit |

|---|---|

| Using Smaller Strips | Easier to conform to tight curves and shapes |

| Pre-Bending Strips | Increases flexibility and makes stapling and gluing canoe strips more manageable |

“Carefully bending the strips to follow the contours of the hull, especially around the more challenging curves and shapes, is crucial for achieving a seamless and durable canoe.”

With patience and practice, you’ll get better at stripping the hull. You’ll be on your way to making a unique cedar strip canoe.

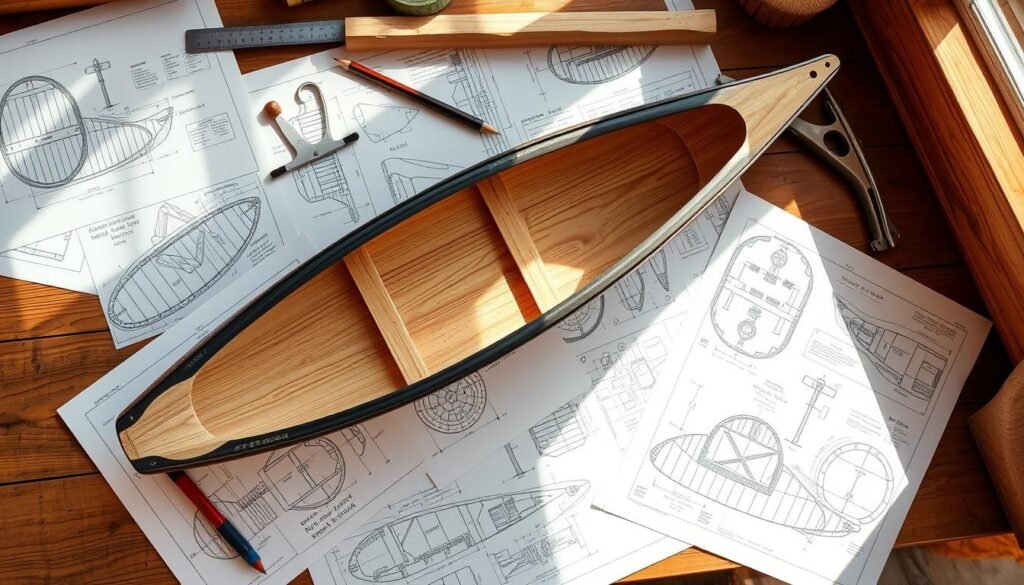

DIY Canoe Plans & Blueprints

Starting your DIY canoe project? You’ll need top-notch plans and blueprints. These guides are key to turning your dream into a real, beautiful canoe. We’ll look at the best places to find these plans, helping you pick the right design for you.

Canoe Plan Sources and Recommendations

Ashes Still Water Boats is a top spot for DIY canoe plans. They have a variety of designs, from cedar strip to composite. Their plans include step-by-step guides, materials lists, and illustrations to help you build.

Wooden Boat Magazine is another great source for DIY canoe plans. They have plans for both classic and modern canoes. Their plans are known for being accurate and reliable.

Choosing the Right Design for Your Needs

Choosing a canoe design is all about what you need and want. Do you want a small solo canoe for fishing or a big one for family fun? Think about your woodworking skills too. Are you a beginner or more experienced?

| Design Considerations | Beginner | Intermediate | Advanced |

|---|---|---|---|

| Intended Use | Recreational, Fishing | Touring, Whitewater | Racing, Expedition |

| Hull Type | Flat, Rounded | Arched, Shallow-V | Pronounced-V, Asymmetric |

| Construction Complexity | Cedar Strip, Plywood | Composite, Skin-on-Frame | Specialized Techniques |

By carefully evaluating canoe plan recommendations and matching them to your specific needs and abilities, you’ll be well on your way to building a truly custom and rewarding DIY canoe.

Fiberglassing the Canoe Hull

After building your DIY canoe’s cedar strip hull, it’s time to add a fiberglass and epoxy resin coating. This step seals the wood, boosts strength and durability, and gives a smooth, water-resistant finish. It protects your canoe.

Applying fiberglass and epoxy to the fiberglass canoe hull is detailed but easy. Here’s what you need to do:

- Clean and sand the cedar hull well. This makes the surface ready for the epoxy resin canoe.

- Cut fiberglass cloth to fit, leaving extra for stems and gunwales.

- Mix epoxy resin as the maker says, then spread it on the hull with a brush or roller.

- Place the fiberglass cloth on the epoxy, smoothing out air bubbles or wrinkles.

- Put a second layer of epoxy over the fiberglass, making sure it’s fully saturated and seals the canoe hull finishing.

- Sand the cured resin for a smooth finish. Add more coats if you want more thickness or look.

Being patient and careful is crucial when fiberglassing the canoe hull. Doing it right means a durable, water-resistant canoe that looks great and lasts long.

| Resin Type | Advantages | Disadvantages |

|---|---|---|

| Epoxy Resin | Excellent adhesion and waterproofing High strength and durability Can be sanded and painted | More expensive than polyester resin Longer curing time |

| Polyester Resin | Less expensive than epoxy Shorter curing time | Lower adhesion and waterproofing Less durable than epoxy |

“Fiberglassing the canoe hull is a critical step that transforms a simple cedar strip boat into a robust, waterproof vessel. With patience and attention to detail, you’ll end up with a canoe that will last for years to come.”

By following these steps and using the right materials, you can make a fiberglass canoe hull that looks amazing and lasts long. The effort you put in will make your DIY canoe project a success.

Installing Gunnels, Decks, and Trim

Now that your DIY canoe’s hull is fiberglassed, it’s time for the next steps. You’ll install the gunnels, decks, and trim. These parts make your canoe look great and add important support and function.

The canoe gunnels are the rails at the top of the hull. They protect the wood and make the canoe stronger. Installing them right is key to finishing your canoe well. The canoe decks at the front and back add beauty and extra space for paddlers.

There are also canoe trim pieces to make your canoe look professional. You can add thwarts, yokes, and more. These pieces fit well with your canoe’s design.

It’s important to plan and do the finishing touches well. This way, your DIY canoe will not only work great but also show your skill and pride.

- Measure and cut the gunnel strips to the proper length.

- Soak the gunnel strips in water to make them pliable for bending.

- Glue and clamp the gunnel strips to the top of the hull.

- Install the bow and stern decks, ensuring a secure and seamless fit.

- Add any additional trim pieces, such as thwarts or yokes, to complete the canoe’s appearance.

“The details are not the details. They make the design.”

By carefully installing the canoe gunnels, canoe decks, and canoe trim, you’ll make your DIY canoe a masterpiece. It will be ready to enjoy the water with both beauty and function.

Finishing Touches: Seats, Yokes, and Varnishing

As you finish your DIY canoe, you’ll add the final touches. These steps make your canoe look great and last longer. You’ll install canoe seats, secure the canoe yoke, and apply canoe varnishing to protect the wood.

The canoe seats are key for comfort and balance. Choosing and installing the right seats greatly improves your paddling experience.

The canoe yoke helps carry the canoe easily. It spreads the weight on your shoulders, making it comfortable to carry.

Lastly, apply a quality canoe varnishing to all wood surfaces. This not only looks good but also protects the wood from damage. It makes your canoe last longer.

“Attention to these finishing touches is what separates a good canoe from a great one. With a little extra care and attention, you can create a truly stunning and long-lasting DIY canoe.”

By focusing on canoe seats, canoe yoke, and canoe varnishing, your DIY canoe will be ready for the water. It will be stylish and durable.

Conclusion – DIY Canoe Plans

Building your own wooden canoe is a rewarding and challenging project. It can result in a unique, personalized watercraft. By following the detailed DIY canoe plans and blueprints in this article, you can make your dream of owning a DIY canoe come true.

Whether you’re a beginner or an experienced woodworker, the sense of accomplishment is immense. The joy of paddling your own handcrafted custom wooden canoe makes the effort worthwhile.

In this comprehensive guide, we’ve looked at the many benefits of building your own canoe. These include the satisfaction of creating a unique vessel and saving money. You also get to customize it to your liking.

From preparing the strongback and molds to fiberglassing the hull and adding the finishing touches, you now know the cedar strip canoe construction process well.

Whether you build from scratch or use pre-designed DIY canoe plans and blueprints, creating your own canoe is a rewarding journey. It’s an unforgettable experience. Embrace the challenge, improve your woodworking skills, and get ready for countless adventures in your handcrafted masterpiece.

FAQ – DIY Canoe Plans

What are the benefits of building your own canoe?

Building your own canoe is rewarding. You get to create something unique and personal. It also lets you learn woodworking skills. Plus, it might save you money compared to buying one.

What are the key steps in the cedar strip canoe construction process?

The main steps include building the strongback and molds. Then, you prepare the cedar strips. Next, bend and attach the stems. Finally, strip the hull by stapling and gluing the strips onto the molds.

Where can I find high-quality DIY canoe plans and blueprints?

Look for DIY canoe plans and blueprints on websites like Ashes Still Water Boats. They offer guidance on choosing the right design. This depends on your skill level, intended use, and personal preferences.

How do I apply the fiberglass and epoxy resin coating to the canoe hull?

After building the cedar strip hull, apply a fiberglass and epoxy resin coating. This seals the wood, adds strength, and makes it water-resistant. It also gives a smooth finish.

What are the final steps in completing the canoe build?

The last steps are adding seats and a yoke. Then, apply a protective varnish coating to all wooden surfaces. These steps make your canoe look great and ensure it lasts long.